Physical properties of textile fibers?

Fiber length

In physical

properties the most important is the fiber length on which the quality of yarns

depends. For cotton if fiber length increases the quality of yarns will be

good, but this is just opposite for wool. In jute the fiber length is too long

that sometimes the fibers are cut into small pieces.

If the fiber

length is too small it is difficult to produce yarn. Yarn is impossible if the fiber

length is less than 0.5 inch. Thin fibers produce thin yarn and coarse yarn is

produced from coarse fibers.

There are two types of fiber on the basis of length:

Continuous

filament

Staple fiber

Continuous filament

Long and

continuous fibers are called filament. Filaments are continuous in length which

can be used as such form or cut into shorter staple fiber form. These fibers

are collected from both natural and artificial source. Any natural fiber can be

made into a filament. When only one filament is used in a yarn then it is

called mono filament. When more than one filament are used in yarn then it is

called multi filament.

Mono filament →

1.5 holes in spinneret.

Multi filament →

10-100 holes.

Staple fiber

When the length

of fiber is short then it is called staple fiber. Stable fibers are manly

shorter in length and related to natural fiber. All natural fibers without silk

can be collected as staple fiber. Artificial fibers also collected as staple fiber.

Staple fibers

are three types on the basis of length:

Short staple: Length is less than 2 inch.

Medium staple: Length is from 2-4 inch.

Long staple: Length is more than 4 inch.

Strength

The capacity of

a fiber to support a load is known as fiber strength. The strength is described

as tenacity.

Tenacity =

Strength/ linear density.

It is expressed

as CN/Tex or N/Tex. The tensile strength is commonly described as the force

required to reach break the increase in the length before breaking is known as

extension.

Elasticity

It is the

property to recover from deformation. The fiber may be elastic or plastic which

depends upon fiber condition and surrounding environment.

Flexibility

Flexibility is

that property to resist repeated bending and folding.

Cohesiveness

It is the

ability of the fibers to cling together during spinning depends on crimp and

twist. In natural fiber the property comes from nature but in artificial fiber

this property is given by crimping.

Fineness

The term

fineness describes the quality of a fiber. By this, we know how fine a fiber

is. It is expressed by the terms count, tex, denier, tex per unit length etc.

1 Tex = 1

gm/1000m.

1 denier = wt.

in gm/900m.

Fineness affects

some fiber properties. Such as yarn count, yarn strength, yarn regularity etc.

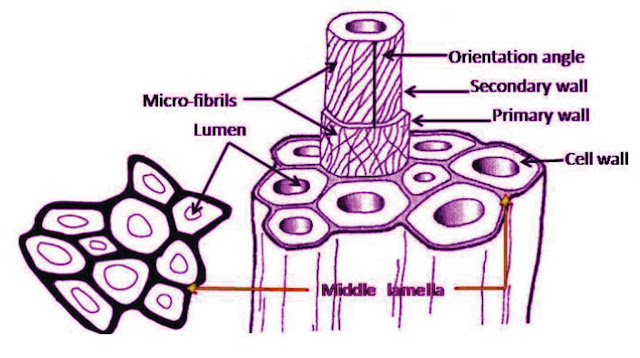

Cross section

The cross

section of a fiber determines the physical properties of fiber. It gives idea

about strength, fineness that varies from fiber to fiber. The cross section

shape of a fiber is important because it contributes to the surface appearance

of the fiber. It helps to give properties of luster, bulk and body of the fibers,

yarn and fabrics. It has effect in twisting, bending or shunning.

Crimp

It refers to the

waves or bends that take place along the length of a fiber. It increases

cohesiveness and resilience, resistance to abortion and gives increased bulk or

warmth to fabrics. It also helps fabrics to maintain their softness or

thickness, increase absorbency and show contact comforts bid reduces luster. A fiber

may have one of the three types of crimp. Namely – Mechanical crimp, natural

crimp or Inherent crimp and Chemical crimp.

Resiliency

It is the

property of a fiber, which enables it to recover from certain load or stretch

over a period of time.

Toughness

The ability of a

fiber to endure large permanent deformations without rupture is called

toughness.

Work of rupture

The area below

the stress –strain curves provides a measure of the work required to break the fiber.

It is called work of rupture and it commonly expressed in CN/Tex.

Appearance

It is expressed

by length, fineness, cross-section cleanness and luster of a fabric. Generally

short fibers are bulky and loss lustrous.

Density

The density

indicates the mass per unit volume. The specific gravity of a fiber indicates

the density relative to that of water at 4 degree Celsius.

Elongation

It is the

ability to be stretched, extended or lengthened. Elongation vary at different

temperatures and when wet or dry.

শেয়ার করুন

এ বিভাগ হতে আরও কিছু পোষ্ট

Our trained chemists work on custom projects designed specifically for the needs of each client. Physical Properties of Solvents

Reply